Lubrication plate

Availablity

In Stock

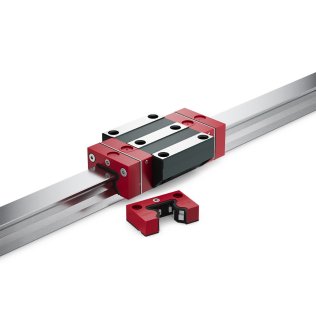

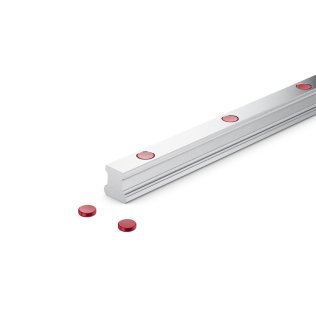

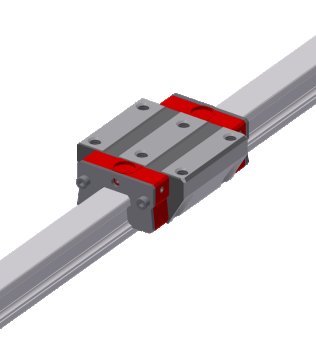

An SPL lubrication plate is a device used in applications where long lubrication intervals are required. It has an integral oil reservoir that ensures a steady and uniform supply of lubrication to the rolling elements over an extended period. It is typically used in dry and clean environments such as handling technology and on the ancillary axes of machine tools.

The advantages of using SPL lubrication plate are:

- Assured supply of lubrication in any installation position

- Long lubrication intervals of up to 5,000 km or 12 months, depending on usage

- Refill apertures closed with screws

- Reduced lubrication and accessory costs

- Low environmental impact due to minimal lubricant consumption

- Wipers have a longer service life as oil is also supplied to the top surface of the rail

For maximum travel distances without re-lubrication, SPL lubrication plates are always used in pairs, and the carriages are given an additional filling of grease. They have the same dimensions as the carriage front plates and are installed in front of them. Retrofitting is possible. In applications where particles of dirt can come into contact with the guideways, additional ZBV wipers must be provided.

- Assured supply of lubrication in any installation position

- Long lubrication intervals of up to 5,000 km or 12 months according to use

- Refill apertures closed with screws

- Reduced outlay on lubrication and accessories

- Low environmental impact thanks to minimum consumption of lubricant

- Wipers have a long service life as oil is also supplied to the top surface of the rail

- The Lubrication plates have the same dimensions as the carriages front plates

- Used in dry and clean environments i.e. on the ancillary axes of machine tools

- Accessory MONORAIL BM

The advantages of using SPL lubrication plate are:

- Assured supply of lubrication in any installation position

- Long lubrication intervals of up to 5,000 km or 12 months, depending on usage

- Refill apertures closed with screws

- Reduced lubrication and accessory costs

- Low environmental impact due to minimal lubricant consumption

- Wipers have a longer service life as oil is also supplied to the top surface of the rail

For maximum travel distances without re-lubrication, SPL lubrication plates are always used in pairs, and the carriages are given an additional filling of grease. They have the same dimensions as the carriage front plates and are installed in front of them. Retrofitting is possible. In applications where particles of dirt can come into contact with the guideways, additional ZBV wipers must be provided.

- Assured supply of lubrication in any installation position

- Long lubrication intervals of up to 5,000 km or 12 months according to use

- Refill apertures closed with screws

- Reduced outlay on lubrication and accessories

- Low environmental impact thanks to minimum consumption of lubricant

- Wipers have a long service life as oil is also supplied to the top surface of the rail

- The Lubrication plates have the same dimensions as the carriages front plates

- Used in dry and clean environments i.e. on the ancillary axes of machine tools

- Accessory MONORAIL BM