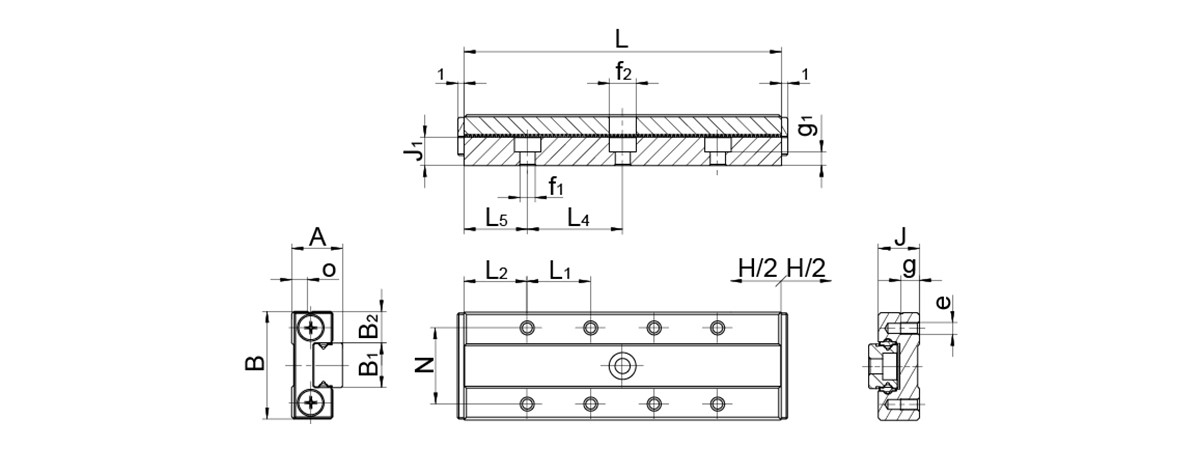

Micro frictionless table Minislide MSQ 7-30.20 (571 010 101)

Item #:

571 010 101

Availablity

In Stock

Typically ships within 4-6 weeks

MINISLIDE are a new generation of miniature guides designed for demanding applications, known for their robustness, high running culture, precision, and reliability. The MSQ range comprises of rail widths of 7 mm and 9 mm, which are available in four to five length and lift variants depending on the type. Applications with high accelerations require sophisticated solutions and MINISLIDE MSQ meet these requirements with its unique design featuring integrated cage force control, enabling speeds of 3 m/s and accelerations of 300 m/s².

In each linear guide, the cage can move freely in the longitudinal axis, but due to uneven load distribution, high accelerations, vertical installation or temperature differences, the cage usually moves out of the center, this is known as cage wandering, which impairs the effectiveness of any application.

The MINISLIDE MSQ are equipped with a sophisticated, robust cage constraint control, which eliminates cage wandering. The gears of the forced control are integrated directly into the carriage and rail, and are made of high-quality plastic. With this compact and robust design and a minimum of integrated components, maximum reliability is ensured in every operating situation. A mechanical stroke limiter protects the cage force control mechanism and facilitates assembly and maintenance (should not be used as a path limiter during operation).

MINISLIDE MSQ has four raceways with circular arc profile, arranged in an O-shape, which allows for large internal support distances. In combination with the 90-degree offset raceways, an even and high absorption of forces from all directions as well as high moments of stiffness are achieved.

- 2 sizes

- System lengths of 30 mm to 70 mm

- Strokes of 20 mm up to 58 mm

- Speed up to 3 m/s

- Acceleration up to 300 m/s2

- Zero backlash

- Temperature range of -30°C to +120°C

- High process reliability thanks to cage control

- Maximum rigidity and load capacities

In each linear guide, the cage can move freely in the longitudinal axis, but due to uneven load distribution, high accelerations, vertical installation or temperature differences, the cage usually moves out of the center, this is known as cage wandering, which impairs the effectiveness of any application.

The MINISLIDE MSQ are equipped with a sophisticated, robust cage constraint control, which eliminates cage wandering. The gears of the forced control are integrated directly into the carriage and rail, and are made of high-quality plastic. With this compact and robust design and a minimum of integrated components, maximum reliability is ensured in every operating situation. A mechanical stroke limiter protects the cage force control mechanism and facilitates assembly and maintenance (should not be used as a path limiter during operation).

MINISLIDE MSQ has four raceways with circular arc profile, arranged in an O-shape, which allows for large internal support distances. In combination with the 90-degree offset raceways, an even and high absorption of forces from all directions as well as high moments of stiffness are achieved.

- 2 sizes

- System lengths of 30 mm to 70 mm

- Strokes of 20 mm up to 58 mm

- Speed up to 3 m/s

- Acceleration up to 300 m/s2

- Zero backlash

- Temperature range of -30°C to +120°C

- High process reliability thanks to cage control

- Maximum rigidity and load capacities